Precision Beyond Limits: 10-Year Mastery in Industrial 3D Printing Solutions

AS9100D & FDA-Certified Manufacturer with 2μm Accuracy for Aerospace / Medical / Automotive Innovations

Shenzhen, China | 10 years of technical deep diving | The global industrial giant stealth champion

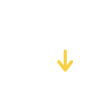

Born in Shenzhen, China's Silicon Valley (2015), we subvert the global cutting-edge manufacturing landscape with 2 micron printing accuracy, hold AS9100D aerospace certification, FDA 510(k) medical access, and EU EN 9100, ISO9001, ISO14001, ISO45001 and other certifications. We are rated as the "Lighthouse of Oriental Additive Revolution" by WIRED.

We currently have more than 800 large-scale industrial-grade 3D printing equipment and high-end CNC equipment, covering SLA service, SLM service, DLP service, SLS service, and MJF service printing processes, and delivering tens of millions of customer products every year. We provide zero tolerance topology optimization solution, unsupported printing solution, and respond to European and American order demands at a fast 72-hour time. It has received orders from customers in more than 50 countries including Siemens Energy (turbo parts), Stacy Medical (orthopedic implants), and the UK University of Technology.

Full-chain control

Full-chain control

From powder metallurgy to post-treatment, fully self-production line

Cost tool

Cost tool

The cost of batch parts is 65% lower than that of traditional processes

Speedy response

Speedy response

Completed from drawings to first sample delivery in 72 hours

Data Think Tank

Data Think Tank

Application scenarios for precise matching of 100,000+ molding parameter library

2 micron precision rewrite precision manufacturing rules

Upload STEP files to get instant quotes (integrated AI analysis function)

Provide free manufacturingability analysis reports (key points of conversion rate improvement)

20+ visual selectors for surface treatment solutions

View the entire process of production nodes to signing in real time

We provide 3D printing parts services ranging from 1 to 100000 pieces,Please email us at xiaojiao2024@gmail.com.

Luotianshan

Luotianshan

Expert of space components manufacturing

Dusi

Dusi

Biomedical application expert

Huanghe

Huanghe

Auto parts manufacturing expert

Xiaoya

Xiaoya

Consumer Electronics Manufacturing Expert

Leiming

Leiming

Industrial Manufacturing Expert

Min. Order: 1 pieces

....