Quality Assurance

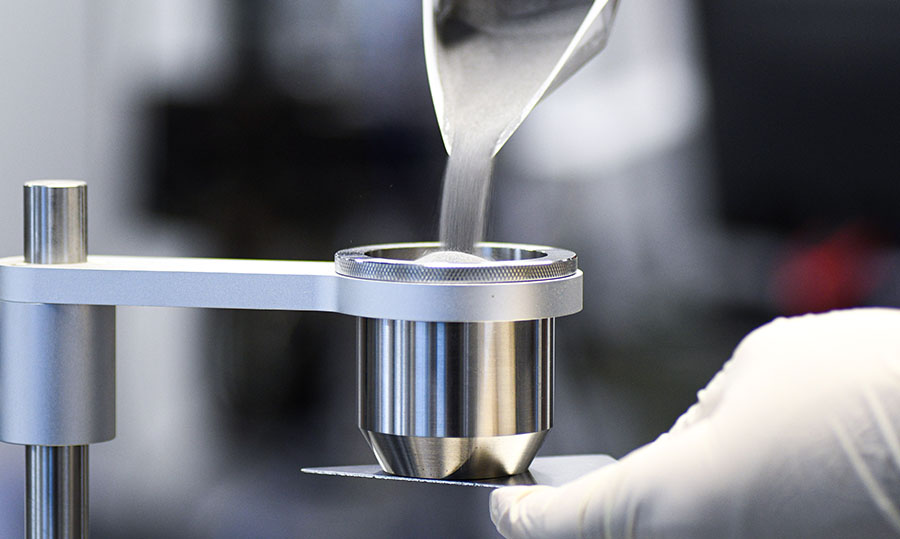

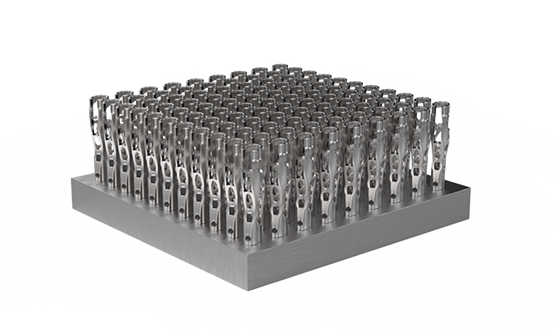

We have obtained ISO 9001, GJB9001C, and AS9100D quality management system certifications, and have dozens of standard testing instruments and equipment for raw material testing, size testing, performance testing, and more. From raw materials to processing to finished product production, we undergo strict testing and monitoring to ensure product quality; At the same time, all records and indicator data are retained in completed reports or records, and can be traced for life.

Luotianshan

Luotianshan

Dusi

Dusi

Huanghe

Huanghe

Xiaoya

Xiaoya

Leiming

Leiming

(+86)135 9042 3495

(+86)135 9042 3495 Building 5, Huafeng Industrial Park, Guangtian Road, Luotian Community, Yanluo Street, Bao'an District, Shenzhen

Building 5, Huafeng Industrial Park, Guangtian Road, Luotian Community, Yanluo Street, Bao'an District, Shenzhen